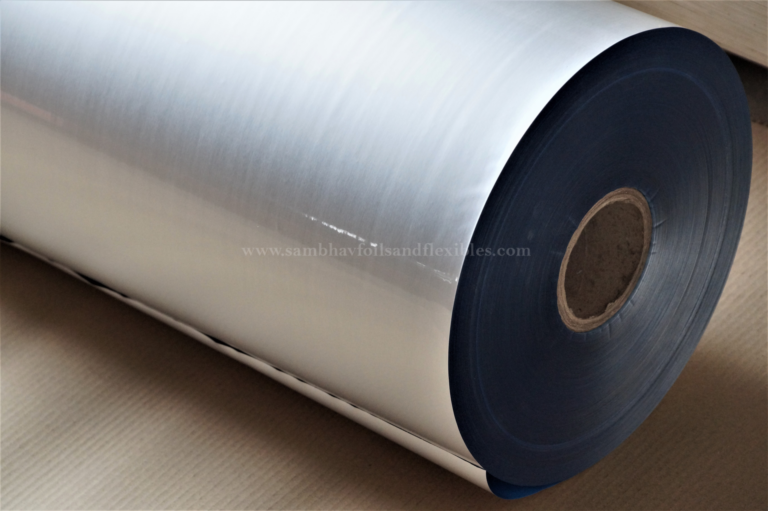

Vacuum Packaging with Aluminium Foil: A Comprehensive Guide for Export and Industrial Packaging

In the world of packaging, ensuring that products reach their destinations safely and intact is paramount. Vacuum packaging with aluminium foil has emerged as a leading solution for both export and industrial packaging, offering unparalleled protection against environmental factors. This article explores the benefits, applications, and selection criteria for vacuum packaging with aluminium foil, providing a comprehensive guide for businesses seeking to enhance their packaging strategies.

Benefits of Vacuum Packaging with Aluminium Foil

- Moisture and Oxygen Barrier: Aluminium foil provides an excellent barrier against moisture and oxygen, which is crucial for preventing corrosion and spoilage in moisture-sensitive goods. Vacuum sealing further enhances this protection by removing air from the packaging, reducing the risk of oxidation and microbial growth.

- Corrosion Protection: By maintaining humidity levels below 40 RH, aluminium foil vacuum packaging prevents corrosion on metal components, making it ideal for industrial and machinery packaging.

- Extended Shelf Life: The combination of aluminium foil and vacuum sealing significantly extends the shelf life of products by preventing spoilage and degradation.

- Enhanced Food Safety: Eliminating oxygen from the packaging reduces the risk of foodborne illnesses, ensuring safer food products for consumers.

- Cost-Effectiveness: By reducing waste and extending product life, vacuum packaging with aluminium foil can be cost-effective in the long run.

Applications of Vacuum Packaging with Aluminium Foil

Food Packaging

- Preserving Freshness: Aluminium foil vacuum packaging is used to preserve the freshness of food products by blocking moisture, oxygen, and light. It is particularly effective for packaging meat products, dried fish, and frozen foods.

- Marinating and Seasoning: Vacuum sealing allows for marinating and seasoning food, enhancing flavor and presentation.

Pharmaceutical Packaging

- Protecting Active Ingredients: Aluminium foil’s barrier properties safeguard pharmaceuticals from environmental factors, ensuring the potency of active ingredients. Vacuum sealing adds an extra layer of protection against moisture and oxygen.

Industrial Packaging

- Corrosion Protection: Aluminium foil vacuum packaging is widely used for protecting machinery and metal components from corrosion during storage and transportation.

- Moisture Control: It maintains a dry environment, preventing moisture-related damage to sensitive electronics and industrial components.

How to Choose the Right Vacuum Packaging with Aluminium Foil

When selecting vacuum packaging with aluminium foil, consider the following factors:

- Thickness and Quality: Ensure the foil is of the right thickness for your product’s needs. Thicker foils offer better protection but may be more expensive.

- Lamination Options: Decide if you need the foil laminated with other materials to enhance its barrier properties or ease of use.

- Customization: Consider if you need custom sizes, shapes, or printing on the packaging to match your brand identity.

- Regulatory Compliance: Ensure that the packaging meets all relevant safety and environmental regulations in your industry.

Export Considerations

For export packaging, vacuum packaging with aluminium foil is particularly beneficial:

- Seaworthy Packaging: It provides protection against high humidity and moisture during sea transport, preventing corrosion and spoilage.

- Customs Compliance: Ensure that the packaging complies with international shipping standards and regulations.

- Partnerships and Distribution: Sambhav Foils promotes partnerships with local distributors to enhance market penetration and customer service.

Conclusion

Vacuum packaging with aluminium foil offers a robust solution for both export and industrial packaging needs, providing unparalleled protection against environmental factors. Its versatility, effectiveness, and cost-efficiency make it an ideal choice for various industries, from food and pharmaceuticals to machinery and electronics. By understanding its benefits and applications, businesses can make informed decisions about when to use vacuum packaging with aluminium foil for their products.