Moisture Barrier Aluminium Foil And Its Uses: Safeguarding The Products In Various Industries

Aluminium foil acts as a moisture barrier has emerged as the need of the hour across numerous industries, including food, pharmaceuticals, electronics, export packaging, etc, because of its unparalleled advantage to protect products from moisture, humidity and oxidation in the environment. It is a versatile material used in the flxible packaging industry, maintaining the integrity and extending the life of sensitive goods.

Properties, applications, and benefits of moisture barrier aluminium foil and how it can be used effectively in different sectors

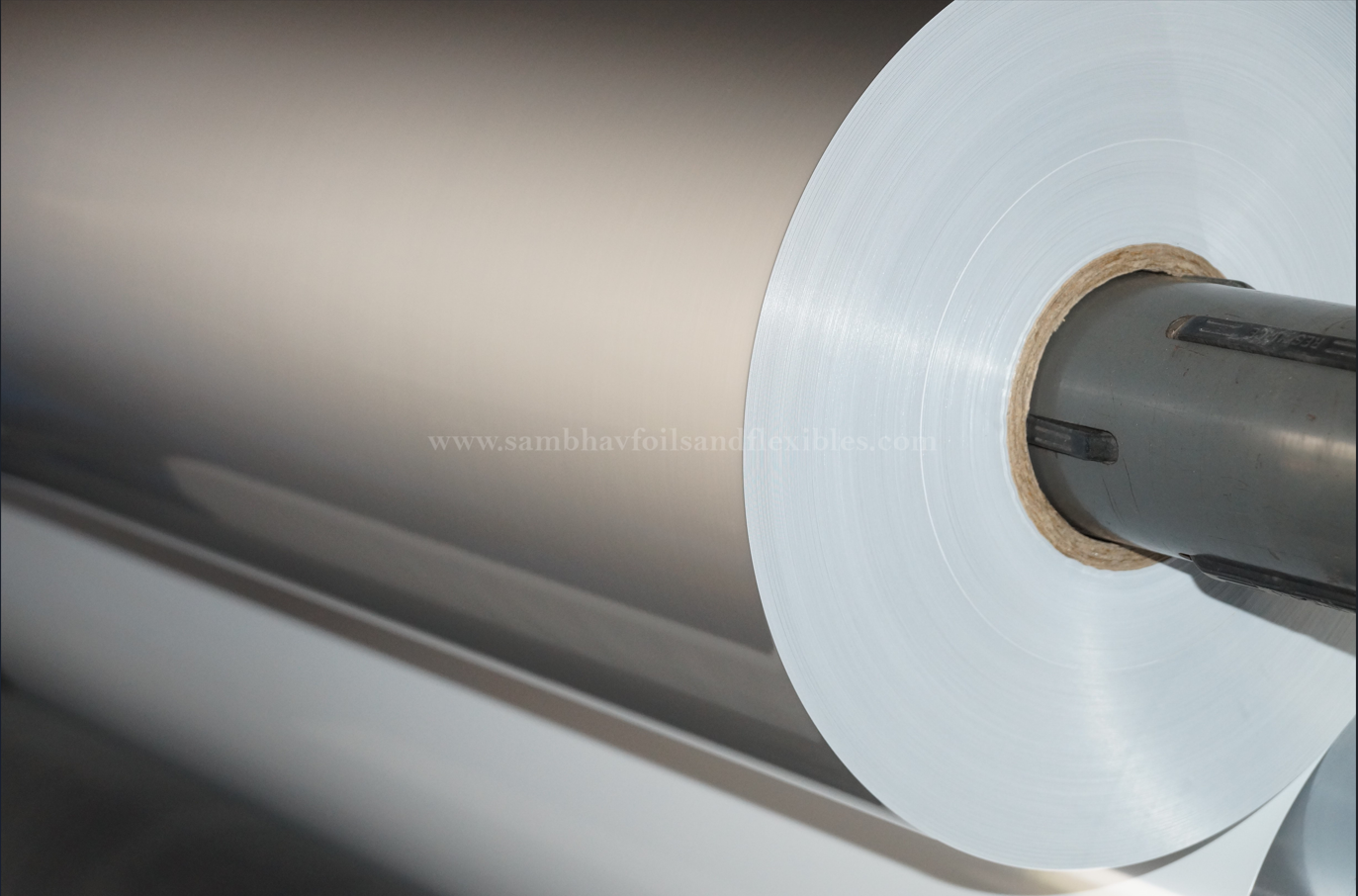

Moisture barrier aluminium foil is a multi-layered composite material consisting of aluminium and other materials, e.g. polyethylene or polyester. The layer of aluminium serves as the first line of defence against moisture, blocking the ingress of water vapour that can contribute to the effects of humidity on products. It also protects from oxygen, UV light and other environmental factors that could diminish any product’s quality.

Moisture Barrier Aluminium Foil Uses

Pharmaceutical Packaging: Moisture barrier aluminium foil bags for pharmaceuticals are generally used to prevent exposure to moisture and oxygen to maintain the potency of drugs. They are commonly used for the packaging of sensitive medications and meet regulatory requirements such as FDA and European pharmacopoeia.

Food Packaging: Aluminium foil is commonly used for the packaging of sensitive food products to preserve them from moisture and contaminants. It works especially well at keeping products fresh and combating spoilage in items, such as snacks, meats and dairy products.

Applying Moisture barrier aluminium foil in Electronics and Sensitive Devices: To protect sensitive electronic components from moisture and corrosion, moisture barrier aluminium foil is used to ensure the functionality (function as intended) of components and sensitivity by preventing the products from corrosion, wear, and defects.

Construction and Insulation: Outside the realm of packaging, aluminium foil is employed as a vapour barrier in construction to prevent moisture accumulation and improve thermal insulation. It reflects 95% of radiant heat and keeps the buildings cool.

Advantages of Moisture Barrier Aluminium Foil

Moisture Barrier: The most important benefit is the moisture barrier properties of aluminium foil that helps in keeping the product intact.

Bio-Environmental Protection: Protects from UV light, oxygen and various gases, which makes it an ideal injectable vial for sensitive products.

Durability and Strength: Aluminium foil has high mechanical strength and is able to withstand handling and transportation stresses.

Customisable: It is possible to customize the structure and laminate it with other materials to improve its barrier properties and to meet individual packaging requirements and preferences.

Choosing Aluminium Foil For The Right Moisture Barrier

If you are preparing the moisture barrier aluminium foil for your products, here are some aspects that you need to consider:

Product Sensitivity: If the product is sensitive, decide how much moisture protection it needs.

Regulatory Compliance: Verify that the foil complies with applicable regulatory requirements, particularly in sectors such as pharmaceuticals.

Customization Capabilities: Choose suppliers that can provide customization to accommodate unique designs and product geometries.

Cost-effectiveness: Weighing cost with improved product protection and avoidance of waste.

Conclusion

Aluminium barrier foil plays a vital role in protecting products from moisture and other environmental factors across many industries. With knowledge of its properties, applications, and benefits, businesses can choose the appropriate packaging solutions to protect their products while improving customer satisfaction. Our custom moisture barrier aluminium foils have become widely popular, and at Sambhav Foils and Flexibles, we aim to provide quality products that are completely customizable and are capable to cater to the varying needs of our clients. By combining quality, innovation, and customer satisfaction, our packaging materials do a wonderful job in protecting your products while also contributing to a thriving packaging industry that is sustainable.